Ultrasonic piezo motors provide very high speed and are typically not used when nanometer level and sub-nanometer level precision is required. Inertia type piezo motors are compact, low cost motors with relatively low force.įlexure-guided / motion amplified actuators provide shorter travel ranges but very high resolution and can be used for continuous scanning applications.

These motors make use of continuous clamp/unclamp and expand/contract cycles of a number of piezo elements. The individual drive concepts are optimized for different applications, they differ in their design, size, cost, force & speed and other performance parameters. For high force and long travel, piezo-walk type motors are recommended. Piezo Motors are intrinsically vacuum compatible, non-magnetic and self locking at rest, providing long travel compared to traditional piezo mechanisms. Piezo nanopositioning motors are based on different drive principles.

#Piezo motor iso#

The company has been ISO 9001 certified since 1994 and provides innovative, high-quality solutions for OEM and research.Nanopositioning Motors, Piezo Actuators XYZ Stages Single Axis Stages 6-Axis Stages Tip/Tilt Stages PI has been developing and manufacturing standard & custom precision products with piezoceramic and electromagnetic drives for 4 decades. PI is a leading manufacturer of precision motion control equipment, piezo systems, piezo motors and actuators for bio-nano-technology, semiconductor, medical engineering and photonics applications. Semiconductor Test & Metrology Instrumentation, Aerospace, High Energy Physics, Optics & Photonics, Precision Motion Control, Microscopy In addition to a long-range step mode a high dynamics sweep / scanning mode is also available, enabling picometers of resolution and kHz range bandwidth. PiezoWalk motors are very robust and can provide high forces to 800 N. They are based on several preloaded actuators performing coordinated motion similar to the way humans walk. These are the most complex of the three motor types. Their motion is very smooth, and forces on the order of 5 to 15 N are typical. These piezo motors provide the highest velocities, typically from 100 mm/sec to 1000 mm/sec. Ultrasonic Motors (resonant piezo motors)

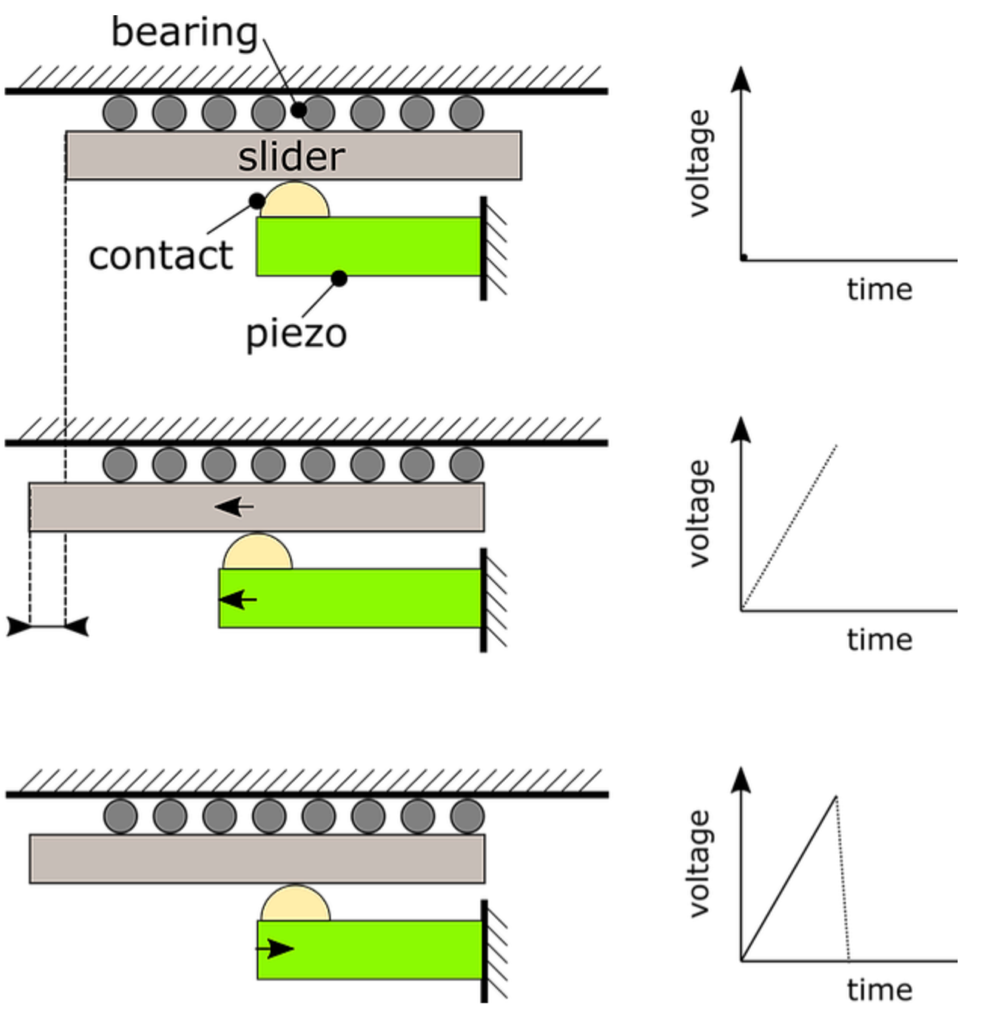

PI’s latest generation achieves a breakthrough in speed – up to 10 mm/sec and provides forces to 10N. Due to their small size they lend themselves to the integration into miniature positioning stages, such as linear and rotary positioners. Their motion is based on a piezoceramic element that expands slowly and then retracts very quickly. These piezo motors are very compact and economical. These novel motors and actuators are also available fully integrated in precision positioners from miniature linear stages to 6-axis Hexapods and Z/tip/tilt platforms. The piezo motor brochure can be downloaded at:Īll three types of piezo motors are self-clamping at rest (no energy consumption, very high stability) and the technology is intrinsically non-magnetic and vacuum compatible. In addition to applications and commercially available products with drawings and technical data, background information on the operating principles and physics behind of each type of motor is available. The 70 page brochure covers three different types of piezo motors – inertial motors, often referred to as stick slip motors, ultrasonic motors and stepping (walk) type motors.

PI, a leading manufacturer of piezo positioning equipment has released a new catalog on piezoelectric motors.

0 kommentar(er)

0 kommentar(er)